Precision Requirements for Ball Screws

The precision requirements for ball screws are very high, but they can vary depending on specific situations. The smaller the gap between the shafts, the higher the accuracy during directional transmission. Ball screws ensure the reliability and sustainability of linear motion. To ensure their continuous effectiveness, it is important to maintain high consistency during reverse transmission.

Ball Screws as Mechanical Linear Actuators

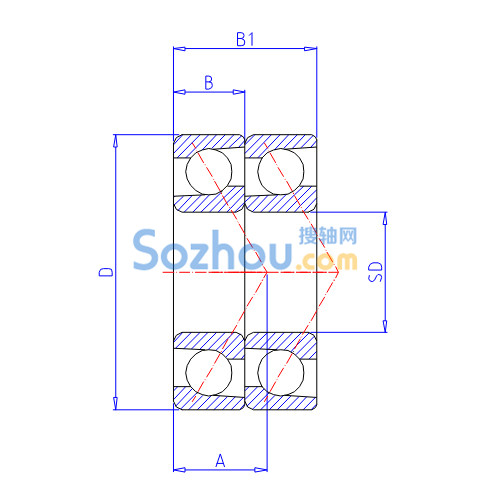

Ball screws are mechanical linear actuators that convert rotational motion into linear motion with minimal friction. The threaded shaft provides a helical raceway for the ball bearings, functioning as a precision screw. In addition to being able to apply or withstand high thrust loads, they operate with minimal friction. They have precise tolerances, making them suitable for applications that require high accuracy.

The ball assembly acts as the nut, while the threaded shaft serves as the screw. Compared to traditional lead screws, ball screws tend to be larger due to the need for a recirculating ball mechanism. Another form of linear actuator based on a rotating rod is the non-threaded ball screw, also known as a “rolling ring drive.”

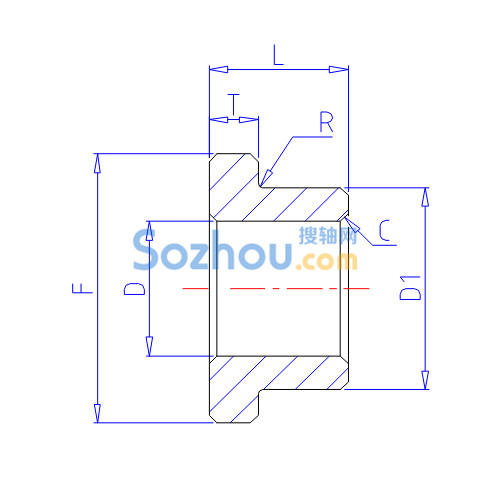

In this design, three or more roller bearings are symmetrically arranged in a housing around a smooth actuator rod or shaft. The bearings are angled relative to the rod, determining the direction and rate of linear motion per revolution of the rod. This design offers advantages over traditional ball screws or lead screws by eliminating backlash and load issues caused by preloaded nuts. The shaft provides a helical raceway for the ball bearings, functioning as a precision screw.