In high-end equipment manufacturing, the accuracy and reliability of linear guide rails directly determine equipment performance. As an industry technology leader, Nadberg delivers breakthrough solutions for CNC machine tools, semiconductor equipment, and other applications through material innovation and structural optimization.

I. Nanometer-Level Precision & Stability

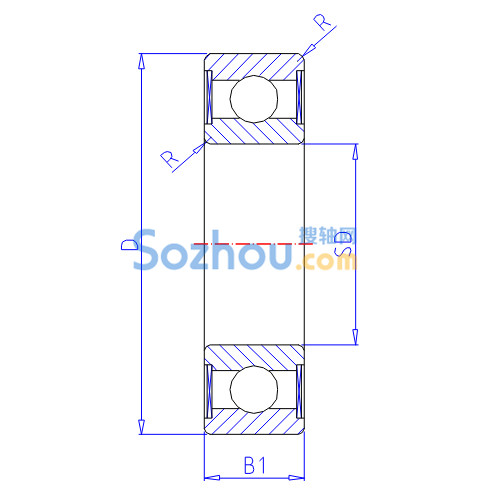

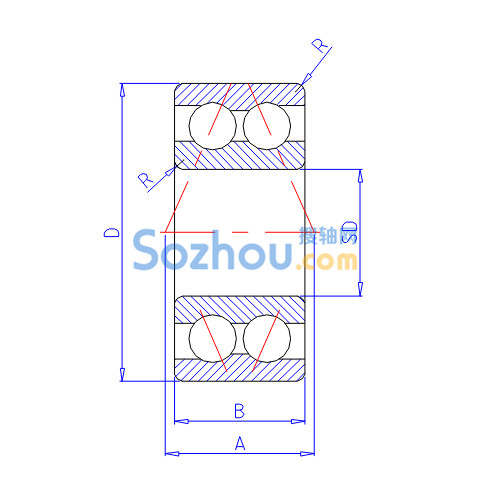

Nadberg guide rails utilize vacuum-quenched GCr15 bearing steel as the base material, achieving a surface hardness of HRC64. Paired with laser-micro-engraved raceway technology, they maintain parallelism errors within ±0.5μm/300mm. In five-axis machining center tests, their repeat positioning accuracy reaches 0.002mm—60% higher than traditional guide rails. The unique 45° four-row ball design ensures balanced radial and lateral load distribution, effectively suppressing vibration deformation.

II. Extended Lifespan & Low Maintenance

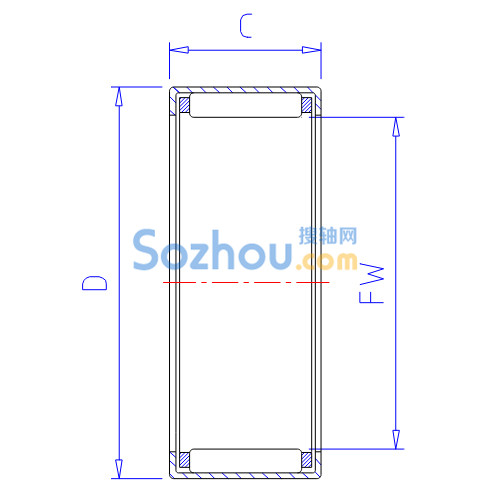

With ceramic coating and self-lubrication technology, the friction coefficient is reduced to 0.001, cutting wear by 90%. In continuous impact testing on automotive welding production lines, Nadberg guide rails achieved a lifespan exceeding 150,000 km—three times longer than standard products. Their sealed structure blocks particles larger than 5μm, meeting Class 100 cleanroom requirements.

III. Modular Adaptability & Smart Integration

The product lineup ranges from MGN7 (miniature) to R3102 (heavy-duty), with single-rail load capacities spanning 10kN–98kN. Widened sliders increase static moment capacity by 100%, ideal for high-center-of-gravity applications like robot joints. Built-in RFID chips enable real-time wear data transmission to MES systems for predictive maintenance.

IV. Energy Efficiency & Cost Benefits

The rolling friction design reduces equipment energy consumption by 18%. In a logistics warehouse project, sorting efficiency improved by 166%. The error averaging effect lowers requirements for base component machining, cutting overall manufacturing costs by 25%.