Natebon deep groove ball bearings are pivotal components in industrial machinery, renowned for their superior performance and diverse applications. Their design integrates advanced engineering and material science, meeting modern demands for efficiency and reliability.

Key Features

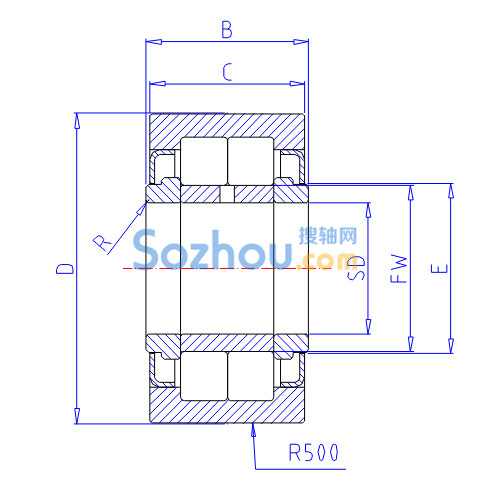

These bearings feature a compact structure that simultaneously withstands radial loads, bidirectional axial loads, and tilting moments, ensuring high rigidity. With low friction coefficients and high-speed capabilities, they maintain stability and durability under demanding conditions, minimizing maintenance needs. A slight self-aligning ability accommodates minor shaft misalignments without compromising performance. Sealed variants, including dust covers and contact seals, effectively prevent contamination, enhancing longevity. Precision manufacturing ensures quiet operation, boosting overall equipment reliability.

Applications

Natebon bearings excel in multiple sectors:

Industrial Robots: Used in joints and rotating parts for precise motion control.

Machining Centers: Serve as core components in rotating tables, enabling efficient cutting operations.

Medical Devices: Ensure low vibration and long life in precision instruments, safeguarding patient safety.

Motors and Automotive: Suited for high-speed environments like electric motors and transmissions, optimizing energy efficiency.

General Machinery: From household appliances to heavy equipment, their versatility simplifies maintenance.

Conclusion

Natebon deep groove ball bearings stand out for their structural advantages, high load capacity, and broad adaptability. Whether prioritizing performance or reliability, they provide a robust foundation for modern mechanical systems.