Performance Characteristics of Electric Spindle Components

An electric spindle is a new technology in the field of CNC machine tools that integrates the machine tool spindle with the spindle motor. The spindle is a set of components that include the electric spindle itself and its accessories: electric spindle, high-frequency inverter, oil mist lubricator, cooling device, built-in encoder, and tool changer. Below is a detailed introduction to the performance characteristics of each component of the electric spindle.

1. High-Frequency Inverter

High-Speed Operation: To achieve the high rotational speeds of tens of thousands or even hundreds of thousands of revolutions per minute, a high-frequency inverter is required to drive the built-in high-speed motor of the electric spindle. The output frequency of the inverter must reach several thousand or even several hundred thousand hertz.

2. Oil Mist Lubricator

Lubrication for High Speeds: When the electric spindle operates at extremely high speeds, the centrifugal force becomes very high, requiring an oil mist lubricator to lubricate the spindle. This not only extends the life of the bearings but also significantly reduces resistance, allowing the bearings to function optimally.

3. Cooling Device

Temperature Management: During operation, the electric spindle rotates at very high speeds, causing the surface temperature to rise significantly. To ensure the spindle operates normally and to prevent damage from high temperatures, a cooling system is necessary. This system circulates a cooling agent around the outer wall of the spindle to keep the temperature low. The cooling device maintains the temperature of the cooling agent at a consistently low level.

4. Built-in Pulse Encoder

Automatic Tool Changing and Rigid Tapping: To enable automatic tool changing and rigid tapping without external assistance, a built-in pulse encoder is installed inside the electric spindle. The pulse encoder accurately controls the position of the spindle and coordinates the feed, ensuring precise and coordinated operation.

5. Automatic Tool Changer

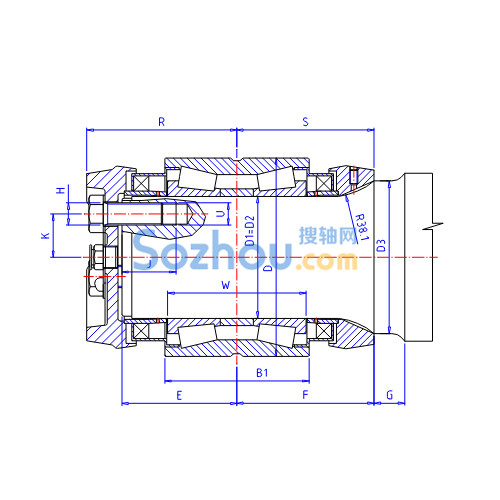

Versatility in Applications: To make the electric spindle widely applicable to various machine tools, an automatic tool changer is installed. This can include components such as butterfly springs or puller oil cylinders. The automatic tool changer allows for quick and efficient tool changes, enhancing the versatility and productivity of the machine tool.

By understanding the performance characteristics of each component of the electric spindle, manufacturers and users can better appreciate the advanced technology and benefits of this integrated system, ensuring high precision, efficiency, and reliability in CNC machine tools.