Guide Systems in Machine Tools

Guide systems enable machine tools to achieve rapid feed speeds. With the same spindle speed, rapid feed is a characteristic of linear guides. Similar to flat guides, linear guides consist of two basic components: a fixed element that serves as the guide and a moving element. Since linear guides are standard components, for machine tool manufacturers, the task is to process a plane for mounting the guide and adjust the parallelism of the guide. To ensure the accuracy of the machine, a small amount of scraping on the bed or column is often necessary. In most cases, installation is relatively easy.

Features of Linear Guides

Movement Mechanism:

No Medium Required: The moving element and the fixed element of the linear guide do not require a medium; instead, they use rolling steel balls.

High Speed and Low Friction: Rolling steel balls are suitable for high-speed movement, have a low coefficient of friction, and offer high sensitivity, meeting the requirements of moving components such as the tool post and slide of a machine tool.

Design of Fixed Elements:

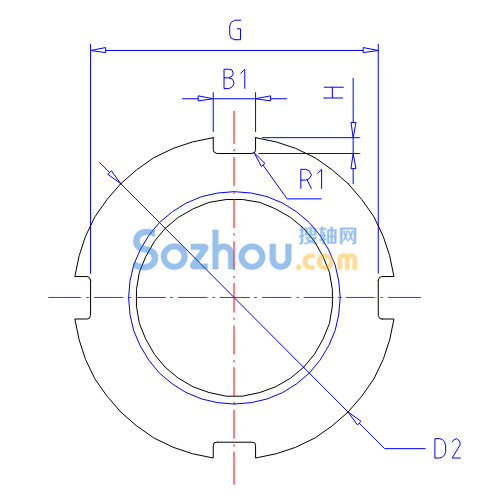

Basic Function: The fixed element (guide) functions similarly to a bearing ring, serving as a support for the steel balls. The support structure is shaped like a "V," covering the top and both sides of the guide.

Support Structure: At least four supports are required to support the working components of the machine. For larger working components, more than four supports may be used.

Comparison with Flat Guides:

Complex Geometry: The cross-sectional geometry of linear guides is more complex than that of flat guides. This complexity arises from the need to process grooves to facilitate the movement of the sliding elements.

Groove Design: The shape and number of grooves depend on the desired function of the machine.

Contact Area:

Gothic Arch (Pointed Arch): The shape is an extension of a semicircle, with the contact point at the apex.

Circular Arc: This shape serves the same purpose as the Gothic arch. The goal is to maximize the contact between the rolling steel balls and the guide (fixed element).

Maximizing Contact Area: The design of the guide system aims to maximize the contact area between the fixed element and the rolling elements. This increases the system's load-carrying capacity and allows it to withstand intermittent or heavy cutting forces by distributing the load over a larger area.

Groove Shapes: There are various groove shapes, with two representative types:

Wear and Preload:

Wear Distribution: As the working components of the machine move, the steel balls roll back and forth in the grooves of the supports, distributing the wear evenly among the steel balls, thereby extending the life of the linear guide.

Preload: To eliminate gaps between the supports and the guide, preload can increase the rigidity of the guide system. Preload is achieved by installing oversized steel balls between the guide and the supports. The diameter tolerance of the steel balls is ±20 micrometers, with increments of 0.5 micrometers. Steel balls are sorted and classified accordingly and installed on the guide.

Balancing Preload: The amount of preload depends on the force applied to the steel balls. If the force is too high, the increased preload can lead to higher resistance to movement. Conversely, reducing the preload can increase the system's sensitivity but may compromise movement accuracy and consistency. This is a balancing act.

Maintenance and Replacement:

Wear and Precision Loss: Over time, the steel balls begin to wear, causing the preload to decrease and leading to a decline in the movement accuracy of the machine's working components. To maintain initial precision, the guide supports may need to be replaced, and in some cases, the entire guide.

System Precision: If the guide system already has preload and the precision is lost, the only solution is to replace the rolling elements.

By understanding the design and features of linear guide systems, machine tool manufacturers can ensure high precision, efficiency, and reliability in their machines.