1. Mechanical Foundation of High-Precision Transmission

With a friction coefficient of 0.001-0.005, ball screws achieve 1/10 the resistance of sliding screws. For example:

C3 grade exhibits ≤±0.003mm positioning error over 300mm, with ±0.001mm repeatability;

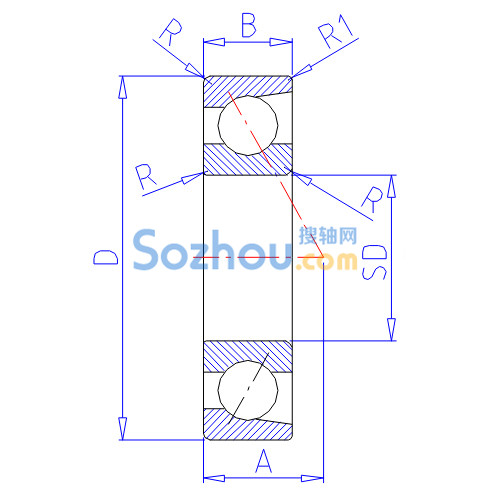

Material selection: Suj2 bearing steel (HRC58-62) ensures Ra≤0.4μm raceway roughness;

Preload control: Dual-nut preloading (10%-15% dynamic load capacity) balances rigidity.

2. High Load-Bearing Mechanisms

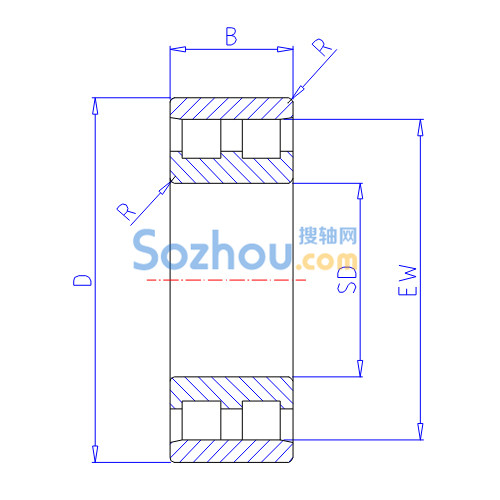

SFU2505 models (25mm diameter) offer 15kN dynamic/28kN static loads, enabled by:

Load distribution: Three-row rollers separately handle axial/radial loads with line contact;

Dynamic rigidity: Planetary roller screws achieve 3-5× higher stiffness via preload-induced repulsion.

3. Maintenance Best Practices

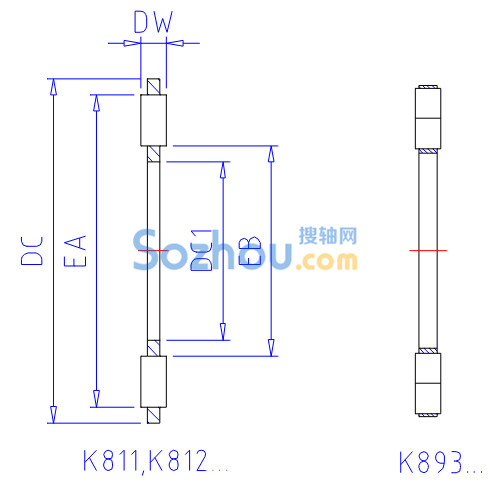

Alignment: Parallelism to rails ≤0.02mm/m, fixed-fixed support for long strokes;

Lubrication: EP lithium grease with centralized systems extends intervals to 500h;

Monitoring: Vibration sensors detect early spalling; backlash threshold ≤0.001mm.