Ball screw pairs are high-precision and widely used transmission devices in mechanical systems. As a common transmission component, it's essential to understand them in depth. In previous articles, we introduced ball screw pairs and their characteristics. Below, we will explain the differences between internal and external circulation in ball screw pairs.

Ball screw pairs typically have two circulation methods: external circulation and internal circulation.

External circulation: The balls intermittently disengage from the screw during circulation.

Internal circulation: The balls remain in constant contact with the screw.

Each complete ball circulation path is called a "circuit," and the number of leads per circuit is referred to as "turns." Internal circulation nuts usually have 2–5 circuits, with one turn per circuit.External circulation nuts often have 1.5, 2.5, or 3.5 turns per circuit.

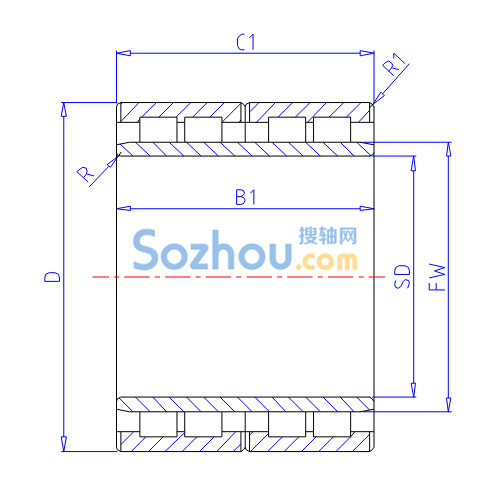

1. External Circulation

In external circulation, balls exit the nut through spiral grooves or tubes on its outer surface before re-entering the screw-nut interface. Common types include:

End-cap type

Tube-insert type (simple structure but prone to wear)

Spiral groove type (compact but less rigid)

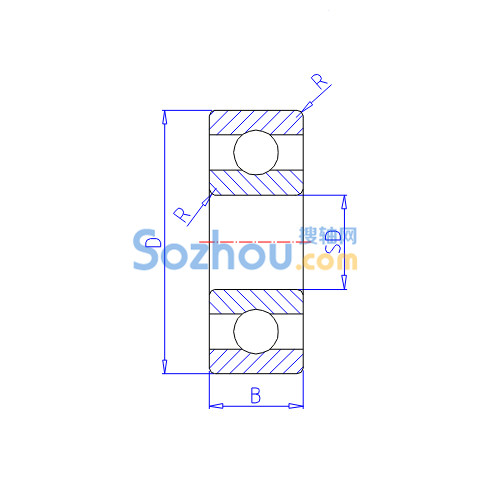

2. Internal Circulation

Internal circulation uses reversers to guide balls. Two main reverser designs exist.:

Cylindrical key reverser: Embedded in the nut with directional grooves.

Edge-insert reverser: More compact but requires higher machining precision.

The above explains the key differences between internal and external circulation in ball screw pairs. For further inquiries, please contact us.