What are the product features and applications of robotic arm modules?

Robotic arm modules can achieve linear and curved motion of loads through the combination of various units, making light-load automation more flexible and precise. They have been widely applied in various types of equipment. Here are some applications:

Easier Detection and Comprehensive Equipment: Features include positioning accuracy, repeatability, and ease of detecting starting torque during operation and parallel functions.

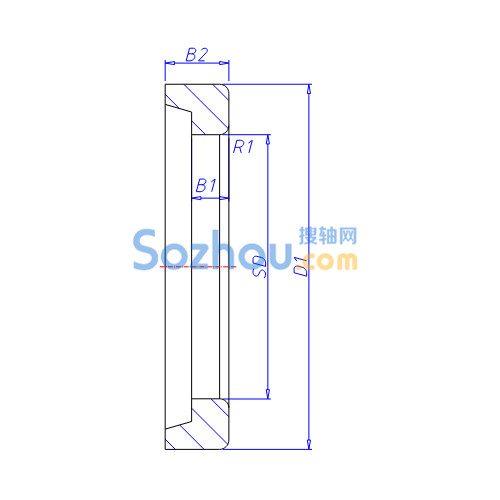

High Precision and Rigidity: The design incorporates deformation analysis of contact positions to enhance accuracy and rigidity. Finite element method optimization is used to achieve the best stiffness-to-weight ratio.

Easy Assembly and Maintenance: Assembly can be done without specialized confirmation. The modules maintain good lubrication even after exposure to dust, making maintenance convenient and allowing for easy recycling of components.

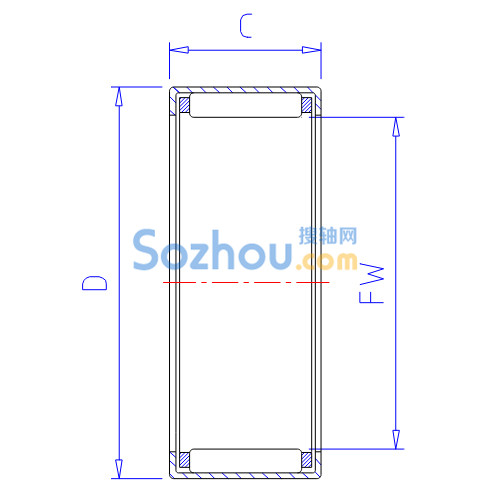

Multiple Designs: Integrated drive mechanisms such as ball screws and U-shaped guide rails provide precise linear motion and compatibility with standard accessories. This enables convenient multi-functional applications while meeting high-precision linear actuator requirements.

Compact Size and Lightweight: U-shaped rails serve as guiding tracks, significantly reducing installation volume. The optimized design using finite element methods ensures an ideal stiffness-to-weight ratio. The system provides smooth motion with low torque and inertia, reducing energy consumption.